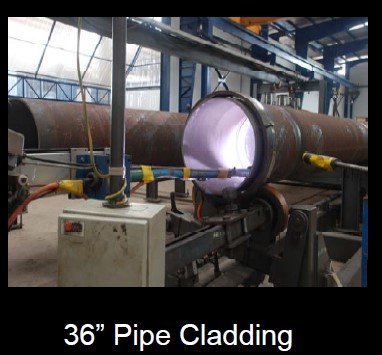

Deema through its clients offer weld overlay bimetal cladded / lined pipes, Mechanically Lined Pipes (MLP), flanges, fittings, and valves. The products offered are manufactured in state-of-the-art facilities in different countries. Our client is one of the biggest cladded equipment manufacturers approved by leading companies like ARAMCO, SABIC, ADNOC, EIL etc. to name a few.

What is A Bi-Metal pipe?

01. A Bi-Metal pipe is a high strength carbon steel carrier pipe with a Corrosion Resistant Alloy (CRA) liner.

02. Outer pipe is seamless or welded carbon steel pipe to API 5L or DNV OS F101, with yield strengths between 350 to 550MPa (X42 to X80).03. Liner pipe is welded CRA with wall thickness of 1mm to 6mm, frequently 2.5 to 3mm.

04. Typical CRA Liners: 316L, 904L, 825 and 625

05. CS Pipe Sizes from 4” to 26” with wall thickness from 5mm to 65mm

06. Pipe Lengths – 6, 12 and 24 meters

Some of the advantages of cladded pipes are follows.

- Low whole of life cost – REDUCED

- High reliability – LOW RISK

- Eliminate Chemicals, Chemical Injection Skids, chemical supply logistics.

- Reduce Lost/Deferred Production due to low down time due to reduced or eliminated pigging.

- When Carbon Steel and inhibitors won’t work due to temperature, pressure, or contaminants.

- High system cleanliness – such as for water injection

- Solid CRA’s require specialized cathodic protection systems.

- Riser fatigue design advantages

Some of the advantages of cladded pipes are follows.

- Low whole of life cost – REDUCED

- High reliability – LOW RISK

- Eliminate Chemicals, Chemical

Injection Skids, chemical supply logistics. - Reduce Lost/Deferred Production due to low down time due to reduced or eliminated pigging.

- When Carbon Steel and inhibitors won’t work due to temperature, pressure, or contaminants.

- High system cleanliness – such as for water injection

- Solid CRA’s require specialized cathodic protection systems.

- Riser fatigue design advantages

Applications of Bi-Metal Pipes

01. Multi Phase Flow-lines

02. Infield Pipelines

03.Risers

04. Production Tubulars

05. Water Injection

06.Slug Catcher Fingers

| Line Pipe Material | Relative Cost vs C-Mn Line Pipe |

|---|---|

| Carbon-Mn Steel(X65) | 1xCS |

| 13% Cr - Super Matertenstic(X80) | 3xCS |

| 22% Cr - Duplex (X65) | 4xCS |

| 25% Cr - Super Duplex (X80) | 5.5xCS |

| X65 31616L - internally Lined | 2.25xCS |

| X65 316L - internally Clad | 4xCS |

| X65 904L - internally Lined | 3xCS |

| X65 825 - internally Lined | 3.25xCS |

| X65 825 - internally Clad | 5.5xCS |

| X65 625 - internally Lined | 5xCS |

| X65 625 - internally Clad | 6.5xCS |